Fruit Crops Manual Revised

Illinois Pesticide Safety Education Manual – Fruit Crops (39-20) was recently revised and is available through the University of Illinois Pesticide Safety Education Program website, at Illinois Extension's online publications store, or at most county Extension offices. Each manual costs $15 plus shipping and handling. The previous edition (39-17) included content for both fruit crop applicators and vegetable crop applicators. That edition has been replaced with two separate manuals, Illinois Pesticide Safety Education Manual: Vegetable Crops (39-19) and Illinois Pesticide Safety Education Manual: Fruit Crops (39-20).

The revised Fruit Crops manual covers topics including integrated pest management strategies, common weeds, insects, and diseases of Illinois fruit crops, as well as pesticide application and calibration for those crops. The manual includes color images for many of the pests, giving applicators an easy-to-use reference for identifying and controlling the many fruit crop pests. The manual is intended to be used in preparation for Illinois Department of Agriculture’s Fruit Crops Pest Control certification exam.

This fruit crops category is for commercial and non-commercial applicators using or supervising the use of pesticides in production of small fruits or tree fruits and nuts as well as on grasslands and non-crop agricultural lands associated with the land on which fruit or nut crops are grown.

Revised Guide on Air Temperature Inversions Available

By Michelle Wiesbrook and Matt Gill, adapted from an email by Andrew Thostenson, North Dakota State University

Listen to the audio version of this article

North Dakota State University (NDSU) Extension has recently released a revised version of their publication, “Air Temperature Inversions: Causes, Characteristics and Potential Effects on Pesticide Spray Drift.” Pesticide applicators can use this detailed guide to help understand and recognize inversions. This knowledge is critical, as spraying during an inversion can greatly increase spray drift.

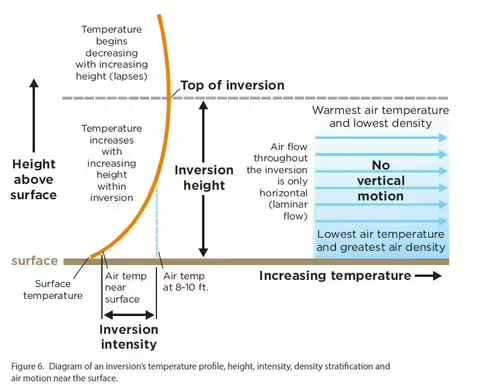

The normal daytime air temperature profile is characterized by decreasing air temperature with increasing altitude. In contrast, an air temperature inversion corresponds to an increase in air temperature with increasing altitude. The real issue with inversions is that air density is inversely related to air temperature. If the air at ground level is at a lower temperature than the air at (for example) 10 feet, then the air at ground level is also denser than the air at 10 feet. The result is very stable air near the ground, allowing only lateral movement of air within the height of the inversion. Spray droplets released in these conditions, especially when humidity is also high, are at risk to drift much longer distances than would be possible during normal air temperature conditions.

The guide characterizes inversions and explains how clouds, wind, and surface conditions come into play. One must-read section focuses on misconceptions about inversions, such as “cold air and warm air are treated as separate masses”. Truly, there is much information in this guide that would benefit pesticide applicators, and after reading it in its entirety, you may find you know more than your local weathercaster. This publication was first released in 2014. According to Andrew Thostenson, NDSU Pesticide Program Specialist, this revision includes more graphics describing the timing, duration, and intensity of air temperature inversions. These graphics were developed using real world data, collected from weather stations across North Dakota and Minnesota during 2017 and 2018, and really do help to visualize the concepts.

This publication is available online and can be viewed by section or downloaded in its entirety as a pdf. For additional reading on inversions, please read Scott Bretthauer’s article in the November/December 2010 issue of this newsletter.

Much research has been conducted on temperature inversions and the resulting effect on spray drift. The University of Missouri has been leading this charge and they summarize their recent research. Their short video explaining temperature inversions is helpful. When it comes to spraying pesticides and inversions, there isn’t an easy button unfortunately, but there are tools out there to help make good decisions. One example is the Pocket Spray Smart app in the March/April 2017 issue of this newsletter.

Illustration Credits: NDSU

Changes for Dicamba Use on Soybeans in Illinois for 2020

By Maria Turner, adapted from an Illinois Department of Agriculture Press Release

Listen to the audio version of this article

The Illinois Department of Agriculture announced additional dicamba label restrictions for the 2020 growing season. Illinois had the highest record of complaints for dicamba use at 724 for 2019 with most of those occurring in July/August. Dicamba related complaints for previous years were 330 in 2018 and 246 complaints in 2017.

Before dicamba-tolerant crops were introduced in Illinois, the state’s regulatory agency typically dealt with only around 100 pesticide injury complaints per year. With the numbers on the rise, the Illinois Agriculture Director, John Sullivan, determined IDOA will move forward pursuing a Special Local needs section 24(c) label for use of dicamba on soybeans in Illinois in 2020.

FIFRA section 24(c) authorizes state lead agencies such as the Illinois Department of Agriculture to register additional uses of federally registered pesticides. These are also called Special Local Needs or SLN registrations. The SLN permits distribution and use only in the registering state. All SLNs must be submitted to EPA for review subsequent to registration by the state. Illinois specific labels for the use of dicamba on soybeans in 2020 will require the following additional provisions:

- Do not apply dicamba if the air temperature at the field at the time of application is more than 85 degrees Fahrenheit or if the National Weather Service’s forecasted high temperature for the nearest available location for the day of application exceeds 85 degrees F.

- Do not apply dicamba after June 20, 2020.

- Before applying dicamba, the applicator must consult the FieldWatch sensitive crop registry and comply with all associated record keeping label requirements.

- Maintain the label-specified downwind buffer between the last treated row and the nearest downfield edge of any Illinois Nature Preserves Commission site.

- It is best to apply dicamba when the wind is blowing away from sensitive areas, including but not limited to bodies of water and nonresidential, uncultivated areas that may harbor sensitive plant species.

These new cutoff requirements are in addition to the federal label requirements that apply to Engenia, XtendiMax, FeXapan and Tavium. Illinois is the first state to announce stricter requirements for the coming year in an attempt to give farmers answers as they purchase seed for next season.

For more information

New Working Group Focused on Dicamba and 2,4-D Drift Risk

By Maria Turner and Michelle Wiesbrook, adapted from a press release from the North Central IPM Center

Listen to the audio version of this article

The North Central IPM Center has awarded a $20,000 grant to the North Central Region Herbicide-Drift Risk Management Working Group. The group has been tasked with developing and disseminating new resources for both row crop and specialty crop farmers, in order to assess and manage drift-damage risk. Certainly, we have seen more instances of herbicide drift damage in recent years, greatly in part due to the expanded use of dicamba on dicamba-tolerant soybeans.

Growing nearby these soybean and corn fields are horticultural crops. The North Central region produces vegetables, fruits, wines, and organic certified products. These are among the fastest growing sectors of the U.S. agriculture industry. Unintended drift can result in yield loss to these sensitive crops. The expanding use of highly phytotoxic herbicides that contain dicamba and 2,4-D chemicals are threatening their survival and profitability. Additionally, according to a recent report by the Weed Science Society of America, damage has also occurred in home gardens, landscape plants and natural vegetation including trees – cypress and certain oak species, and native herbaceous ground cover that serves as food for pollinators. This group will serve to increase awareness in these areas and provide needed resources.

This working group will be made up of a variety of stakeholders, including weed, agronomic, and horticulture crop specialists. The group will help all farmers recognize and respond to dicamba and 2,4-D drift risk. They are hopeful that these efforts will result in more exact exposure numbers. For more information about this group and its efforts please contact Ethan Stoetzer with the North Central IPM center.

Winterizing Your Spray Equipment

By Maria Turner

Listen to the audio version of this article

Now is the time to service and winterize your equipment. Your sprayers should be at the top of that list. The end of the season is an excellent time to conduct a deep cleaning and inspection of all your sprayer’s components. This inspection will ensure that your sprayer is free of residues, properly functioning, and ready for those early in the spring applications.

Ideally, you should be thoroughly cleaning your sprayers on a regular basis, especially as you switch pesticide formulations. Regular cleaning helps to remove pesticide residues that could cause cross-contamination with other pesticides or fertilizers, possibly resulting in turf injury. Trace amounts of one pesticide can react with another or carry-over to the next spraying, causing damage, especially with herbicides. Thoroughly cleaning your sprayer at the end of the season will also help extend the lifespan of its components. Some pesticide formulations are corrosive, and even small amounts of residue can damage sprayer components, including stainless steel tips and fiberglass tanks when left for extended periods, like overwinter.

Thoroughly clean the spray tank, including all irregular surfaces, such as baffles, plumbing fixtures, and agitation units. The inside of the top of the spray tank is often forgotten and should be cleaned as well. Many applicators incorrectly focus all of their attention on cleaning the sprayer’s tank. Even after cleaning a spray tank, residues may remain in the sprayer’s screens, filters, and plumbing. Inspect all hoses for wear or tear and for residues that often accumulate in dips and low areas. Check sprayer parts that have dead ends, like the boom’s end caps.

Consult the pesticide label(s) for information on cleaning the sprayer and disposing of rinsates. Some pesticide labels will provide recommendations for specific tank cleaners and instructions for how to properly dispose of rinsates. Even though you will be dealing with a product that is very dilute, it doesn’t mean that you don’t need to use Personal Protective Equipment (PPE).

The next step in the winterization process is to remove as much water from the system as possible. This can be done by allowing the pump to push water through the lines, and then by opening all the valves and allowing the water to drain. Some sprayer’s manuals also recommend using compressed air to blow out hosing and manifolds.

Despite your best efforts, water will likely remain in various parts of the sprayer. That remaining water could freeze, expand, and damage your sprayer. The last step when winterizing is to displace and dilute the remaining water with antifreeze. There are different types of antifreeze on the market, so be sure to read the label of the antifreeze to determine if it will work. RV antifreeze, made from propylene glycol, is often recommended because it is inexpensive, works well, and is less hazardous to people, pets, and the environment. To begin, add enough antifreeze into the tank fill to fill the volume of plumbing and hoses. Turn on the sprayer and continue running until undiluted antifreeze exits the nozzles. Be sure to write down how much antifreeze it took to go through the lines so that you will know this for future winterizations.

Proper cleanouts and winterization, while time-consuming, are essential tasks for maintaining your spray equipment. Saving time by skipping steps can result in costly damage and possibly a delayed start while trying to fix all the broken or burst lines. Take the time now to winterize your sprayer properly and be ready for next season.

For more information

Illinois Pest Alert: European Pepper Moth (Duponchelia fovealis)

Listen to the audio version of this article

European pepper moth (Duponchelia fovealis) has the potential to become a significant greenhouse pest in Illinois. This pest is not likely to survive winter temperatures in Illinois, but it can live and reproduce in greenhouses year-round on a broad range of host plants (a list of host plants is provided on page 3). It is transported in infested plant stock, so incoming stock should be closely inspected.

Report:

If you find an insect you suspect to be European pepper moth, please contact your local Extension office and do not sell or distribute infested plants. Find your local extension office online.

Life Cycle and Damage:

Adults are active for 1 - 2 weeks. Adult females deposit white-ish eggs on the undersides of leaves. Eggs turn red as they develop, hatching in 4 - 9 days.

Larvae feed on the roots, leaves, flowers and plant debris of host plants. They chew crescent shaped holes in leaves growing near the base of the plant, eventually consuming whole leaves. Larvae can also bore into the stems of host plants, causing instability or collapse of the plant and facilitating infection by fungal pathogens. Damage by this pest can be easily misidentified as fungal disease.

After 3 - 4 weeks of feeding, larvae will produce silk and build cocoons in which they pupate. Cocoons and webbing can be found on the undersides of leaves, along the edges of pots near the soil surface or on the outside or underside of pots. They pupate for 1 - 2 weeks.

The entire life cycle can be completed in 6 - 8 weeks at 68° F, making it possible for a greenhouse to support 8 or 9 generations per year.

Identification:

Moths are 0.35 - 0.5 inches long and have a wingspan of 0.75 - 0.83 inches. The wings are gray to brown with two white to yellow transverse lines. The rearmost line has a distinct rear-facing U-bend (noted with an arrow in Fig. 1)The abdomen is often upturned at the rear end.

Each larva has a dark head capsule and a cream-colored body with dark spots on each segment. The larva has a hard plate on the segment directly behind the head (noted with an arrow in Fig. 2), which distinguishes the larva from species that are similar in appearance, such as sod webworm.

Where to Look:

Inspect plants for:

- Crescent shaped holes and defoliation of leaves near the base of the plant

- Unstable or collapsing stems

- Cocoons and webbing on the undersides of leaves, where leaves meet the soil, along the edges of pots, or on the underside of pots

- Adult moths or eggs on the undersides of leaves

Monitoring traps:

- Species specific pheromone lures can be place inside aquatic traps or delta traps to monitor moth populations.

Cultural and Mechanical Controls:

Exclusion is the most effective way to prevent or limit infestation. Inspect plants for signs of infestation and isolate infested plants to prevent moths from infesting additional plants.

If infested plants are found, freezing temperatures can kill insects within the plants. Pots and greenhouse surfaces can be sanitized to remove larvae or cocoons.

Plant debris and lower leaves can be removed and the media can be allowed to dry to reduce preferred habitat.

Biological Controls:

Treatments containing Bt (Bacillus thuringiensis) microbes are effective in controlling the larvae of many moth species. Bt treatments are most effective on young larvae but are not effective in treating pupae or adult moths. Bt products are applied to the surface of plants a will not reach larvae that have bored into plant stems.

Biocontrol agents such as predatory mites (Gaeolaelaps aculeifer, Stratiolaelaps scimitus), rove beetles (Dalotia coriaria), entomopathogenic nematodes (Heterorhabditis spp., Steinernema spp. or parasitoid wasps (Trichogramma spp.) can be effective in controlling larvae.

Chemical Controls:

European pepper moths have shown no resistance to common insecticides. Contact insecticides applied to the surface of plants are most effective in treating young larvae but will not reach mature larvae that have bored into plant stems. It is sometimes helpful to lay plant pots on their sides so spray treatments can easily be applied to the undersides of leaves.

Always be sure to read and follow all directions on the pesticide label. Do not apply a treatment that is not labeled for your target pest or application site.

References:

2019 Operation S.A.F.E. Fly-Ins: Takeaways

By Matt Gill

S.A.F.E. stands for Self-regulating Application and Flight Efficiency. The program has oversight by the NAAA (National Agricultural Aviation Association) and NAAREF (National Agricultural Aviation Research and Education Foundation). At an Operation S.A.F.E. Fly-In, spray pattern deposition is collected and measured. A certified analyst then processes the data and provides the applicator with printouts of spray deposition across the swath, effective swath width and droplet spectrum information. If corrections are needed, the applicator may adjust the aircraft setup and immediately run another test series to verify that the adjustments have improved the spray pattern or droplet size. Some of the basic adjustments to be made include nozzle orifice size, deflection angle, boom pressure, and spray height. In many cases, an aerial applicator may run multiple series, checking different setups for various spray application rates used across a spraying season.

Each year the Illinois Agricultural Aviation Association (IAAA) holds an Operation S.A.F.E. fly-in at the start of the spraying season. This past spring was a challenge for everyone. With wet fields, late planting and few days with favorable weather to spray, turnout at this year’s fly-in in Manito, IL was lower than usual. However, that was not due to a lack of interest.

With much coordination (and re-scheduling due to weather), 3 “make-up” fly-ins were held across the state at the request of applicators who could not make it to the official IAAA fly-in. In all, 19 aircraft were tested, requiring 141 passes over the flight-line. Remember, the “S” in the S.A.F.E. acronym stands for “Self-regulating.” No entity requires pilots to bring their aircraft to a fly-in—it is completely voluntary. Attending is not inexpensive either: it can cost several thousand dollars for the fuel alone to travel to and participate in a fly-in. That is not to mention the time required, which was in particularly short supply this season. It is a credit to the professionalism of Illinois’ aerial applicators that they prioritize safety and application accuracy so highly.

The University of Illinois was also invited to conduct several fly-ins in Wisconsin, Ohio and South Dakota. A total of 17 aircraft were tested in Wisconsin and South Dakota requiring 186 passes over the flight-line. The fly-in in Ohio was unfortunately canceled after 3 attempts to reschedule due to weather.

This year showed increased interest among aerial applicators to test alternative boom configurations. In particular, many “short-boom” setups were tested. While the industry standard boom width is 75% of the wingspan for fixed-wing and 90% of the rotor span for helicopters, shorter boom widths can often reduce drift potential. This is due to a reduction in the amount of spray being entrained in the wing-tip vortices. With this in mind, some applicators have installed electronic shutoff valves on their booms which allow them to switch in-flight from a “full boom” to a “short boom” when spraying conditions become less favorable. Testing these setups is critical in determining the effective swath width, which is a needed input for the aircraft’s rate controller and guidance system. The results thus far have been mixed. In some cases, reducing boom width has had very little impact on swath width. For example, one test with a Bell 206B (Flat fan nozzles at 90-degrees deflection) showed no reduction in swath width even after shutting off 5 nozzles on each boom end. In other cases, there is a reduction in swath width. One AT-802A (straight stream nozzles at 0-degree deflection) showed that reducing boom width from 75% to 50% reduced swath width from 80 feet to 50 feet (37%). The relationship does seem dependent on the type of aircraft and droplet spectrum, but no hard and fast rules have yet been found.

Another trend this year is the increased use of straight stream nozzles on higher-speed aircraft. Wind tunnel data from the USDA AATRU (Aerial Application Technology Research Unit) has shown that small-orifice straight stream nozzles can provide larger droplet spectrums if operated at higher pressures. Practically, this means using a greater number of nozzles spaced closer together than traditional configurations. Pattern testing these setups has shown them to be more resistant to crosswind effects as expected.

It is immensely encouraging to see aerial applicators continue to push the envelope of technology in pursuit of improving safety and efficacy of their applications. While attending an Operation S.A.F.E. fly-in may only happen once per year, effectively calibrating and pattern testing even a single aircraft can positively impact tens of thousands of acres throughout a spraying season.

Download This Issue of the Newsletter

Download, save, and share the 2019 November/December issue of the newsletter.

Editorial Notes

The development and publication of this newsletter has been supported with funding from the Illinois Department of Agriculture.

Michelle Wiesbrook, Extension Specialist, Pesticide Safety Education

The Illinois Pesticide Review is published six times a year. For more information about pesticide safety or for more issues of this newsletter, please visit us at www.pesticidesafety.illinois.edu. You can also reach us at 800-644-2123.

Disclaimer: Mention of trade names in this newsletter is for general information purposes only and does not constitute endorsement of one product over another, nor is discrimination intended against any product.

Copyright © 2019, Board of Trustees, University of Illinois

We’re on Facebook! Follow us for updates on programs, news, and events.