Illinois Pesticide Review Newsletter

Concise information on legislation, regulations, and other developments directly impacting pesticide use in Illinois.

January/February 2026

In this issue

- Answers to common questions about pesticide licensing, training, and testing

- EPA launches new tools to help applicators meet ESA mitigation requirements

- Certified to apply Paraquat? Has your training expired?

- Promoting safety awareness and practices: February’s National Pesticide Safety Education Month

November/December 2025

In this issue

- Register for in-person pesticide applicator training clinics, testing offered statewide

- Pesticide applicator in-person training and testing locations and dates set for 2025-2026

- Public comment open on proposed rules on barrier mosquito treatment, school application restrictions

- Continuing education units and fee adjustments for Illinois pesticide certification

September/October 2025

In this issue

- Teens demonstrate pesticide knowledge at Youth Crop Scouting Competition

- Protect your eyes while working with pesticides

- Jean Miles retires after 28 years with Pesticide Safety Education Program

- Welcome, Jonathan Jackson!

July/August 2025

In this issue

- Final insecticide strategy brings major changes for applicators

- Household hazardous material collection events scheduled for fall 2025

- EPA opens comment period on Dicamba re-registration for soybeans, cotton with proposed mitigation measures

- Twisted leaves and tough questions: What to do if herbicide spray drift hits your farm or garden

- Guide available on handling pesticide drift complaints

- Upcoming ag related events to check out

May/June 2025

In this issue

- 2025 Agrichemical container recycling program schedule

- USDA rescinds federal restricted use pesticide recordkeeping requirement for private applicators

- Illinois invasive: Elm zigzag sawfly

- Taking a pesticide exam online soon? See these new equipment requirements first

- Phytobac™ breaks down spray tank residues

- Container recycling and the ACRC

March/April 2025

In this issue

- Spring cleaning of pesticide storage areas

- Misuse case summary for 2024 and tips to prevent misuse in 2025

- Protecting pollinators from pesticides

- Training and testing options for the remainder of the pesticide application season

- Pesticide related bills being considered now

January/February 2025

In this issue

- IDOA issues guidance on new law concerning pesticide application in rights-of-way

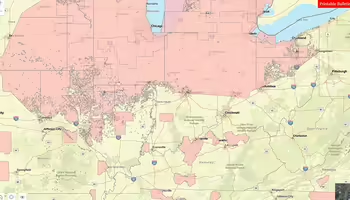

- Public comment opens on monarch butterfly's threatened species status, USFWS contemplates limitations on pesticides

- Updated Worker Protection Standards Application Exclusion Zone requirements

- Managing western corn rootworm while maintaining Bt efficacy

November/December 2024

In this issue

- Revised Pesticide Safety Education publications for 2024-2025

- Pesticide applicator in-person training and testing locations and dates set for 2024-2025

- EPA’s final herbicide strategy for ESA: What could change

- Why insects resist: The underlying mechanisms of insecticide resistance

- EPA releases Rodenticide Strategy, including final biological evaluation on the effects of 11 rodenticides on endangered species and associated mitigation

September/October 2024

In this issue

- Draft Insecticide Strategy released by EPA

- DIY spray and aerosol products likely to fail in German cockroach control

- Emergence of a new Illinois turf pest: The annual bluegrass weevil

- Pesticide Pitfalls: Common Misuses and What to Do If You've Made a Mistake

- EPA issues emergency order to stop all use of the pesticide Dacthal

July/August 2024

In this issue

- Considerations before consuming produce following a pesticide misapplication

- Guide available on handling pesticide drift complaints

- Changes may come to federal pesticide regulations after Chevron ruling overturned

- Online mapping tools help connect growers, beekeepers, and pesticide applicators

- Household hazardous material collection events scheduled for fall 2024

- Here’s what to do if you find spotted lanternfly

May/June 2024

In this issue

- Maintaining personal protective equipment

- Welcome, John Schepis!

- New pesticide laws around schools

- Recognizing heat-related warning signs for gardeners and landscapers

March/April 2024

In this issue

- Pesticide applicators should familiarize themselves with EPA’s Bulletins Live! Two system

- Welcome Instructional Designer, Steven Zhu!

- 2024 Agriculture container recycling program schedule

- New minimum age requirement for Illinois pesticide licenses on the horizon

- Certification exam preparation: tips and accommodations

January/February 2024

In this issue

- Illinois Department of Agriculture updates identification requirements for pesticide certification and licensing

- New pesticide licensing fee schedule in place

- Periodical cicadas of brood XIII and brood XIX emerge at same time!

- Illinois Department of Agriculture announces improvements to search tool for pesticide licensing and product registration

November/December 2023

In this issue

- Pesticide applicator in-person training and testing locations and dates set for 2023-2024

- Quicker check-in process for Illinois Pesticide Safety Education Program clinics

- WPS pesticide safety training requirements refresher: Illinois

- Let your voice be heard! Public comment period on proposed rate changes to chlorothalonil

September/October 2023

In this issue

- Know this for a simplified registration and licensure process

- Illinois Department of Agriculture announces new staff members

- Illinois Department of Agriculture releases pesticide clean sweep program results

- Spotted lanternfly: A new invasive insect in Illinois

- Household hazardous material collection events scheduled for fall 2023

July/August 2023

In this issue

- Tips to help employees succeed

- EPA releases draft herbicide strategy; public comment period open

- Paraquat certification valid 3 years: Are you due for training?

- Online training and testing unavailable beginning August 31

November/December 2022

- Change Coming to How EPA Protects Endangered Species from Pesticides – Feedback Needed

- New Registration and Check-in Process for Illinois Pesticide Safety Education Clinics

- Editorial Notes

- Download This Issue of the Newsletter

- Goodbye to Matt Gill and Maria Turner

Recent Issues